PRODUCTS

AUGERS

In our BOREXO production include a wide Range of Augers for different drilling ground condition according to the Geo – Technical Order (GTO) and various pile diameter. We offer a wide Range of Augers with different types, different categories, and different diameter at the Range of 500mm — 2500mm. The categories followed by single start, double start, Half and double start full spiral.

OUR TYPES ARE:

(i) Soil Augers: Single Start, Double Start with half spiral and full spiral

(ii) Rock Augers: Single Start, Double Start with half Spiral and full spiral

Our BOREXO Augers are classified into following categories:

• Standard: -Suitable for medium and limited hardness (0 – 12.5mpa)

• Heavy-Duty: -Suitable for medium hardness of (12.5 — 50mpa)

• Extra Heavy-duty : -suitable for high hardness of (50 — 100mpa)

SOIL AUGERS

It is suitable for drilling Loose, medium dense soil, gravels and clay with hardness Range of (0-12.5 mpa) Single Start is mainly used for less than equal to 750 mm diameter. Double start is mainly used for greater than 750 to 2500 mm diameter.

TECHNICAL SPECIFICATIONS

Central Pipe

0 = 159/203 mm

Thickness = 30 mm

Flights Thickness = 30/40 mm

Pitch = 300/600 mm

Tung Studs HB 900

Blades

In Hardox HB 400

Thickness = 70 mm

Equipment

Teeth Esco 18TU25T

Rock Pilot bit Interchangeable

Kelly box

200x200 mm

130x130 mm

ROCK AUGER

The Rock Auger is suitable for drilling medium dense gravels, Hard Rock of Hardness range of (12.5 to 50 mpa). Single Start is mainly used less than equal to 750 mm diameter. Double start is main used for greater then 750 to 2500 mm

TECHNICAL SPECIFICATIONS

Central Pipe

0 = 159/203 mm

Thickness = 25/30 mm

Flights

Thickness = 30/40 mm

Pitch = 300/600 mm

Blades

In Hardox HB 400

Rock Pilot bit B47

Kelly box

200x200 mm

130x130 mm

The Rock

BUCKETS

It is difficult task to perform the drilling in open tool condition. So, in advance stages of piling, the Buckets are acting major role to increase productivity. Buckets are designed with closed surface and rotating bottom with an opening. It helps to stop the overflow and to hold maximum soil inside the tool itself. Hence piling should be done without much wastage. Our BOREXO Buckets are designed for all kinds of ground drilling conditions such as hard rocks, gravels, soil and clay. Our Buckets are mainly classified into two major types. The Cylinders and Conical Buckets.

According to its usage majorly classified into three types:

The Soil Buckets, Rock Buckets and Cleaning Buckets.

Our BOREXO Buckets are classified into following categories :

• Standard: Suitable for medium and limited hardness (0 – 12.5mpa)

• Heavy Duty: Suitable for medium hardness of (12.5 — 50 mpa)

• Extra Heavy duty: Suitable for high hardness of (50 — 100 mpa)

SOIL BUCKETS

The Soil Buckets are mainly used for fine grained soil, clay soil, low dense sand, and low dense gravel. Our Soil Buckets are designed into Three types: Standard, Heavy Duty, Extra Heavy Duty.

TECHNICAL SPECIFICATIONS

Shell

Thickness = 20 mm

Height = 1000 mm

Bottoms

Fixed and rotating bottom in

Thickness = 40 mm

Hard faced ribbings HB 600

Blades

Thickness = 40 mm

Equipment

Teeth Esco 18TU25T

Pilot bit

Kelly box

200x200 mm; 130x130 mm

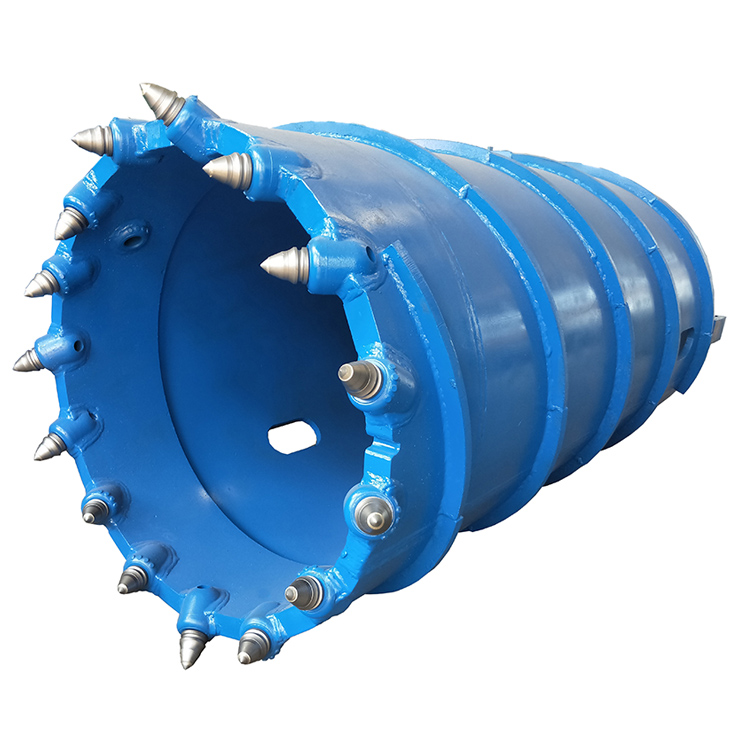

ROCK BUCKETS

The Rock Buckets are to perform Brisement Hard Rock fine

particles and Bentonite (or) polymers are used in this process

to carry out the cutting particles and protect the casing. We

basically design and manufacture Cylinder and Conical Rock

Buckets. We prefer to use our Cylinder Buckets for dense sand, gravel and hard Rocks of >100 mpa and recommend Conical Buckets for soft & stiff, medium dense soil gravel medium coarse gravel. Also designed for Sedimentary and Siliceous Rocks of (50 — 100 mpa)

TECHNICAL SPECIFICATIONS

Shell

Thickness = 20 mm

Height = 1250 mm

Bottoms

Thickness = 40 mm

Blades

In Hardox HB 400

Thickness = 70 mm

Rock Pilot bit

Interchangeabl

Kelly box

200x200 mm; 130x130 mm

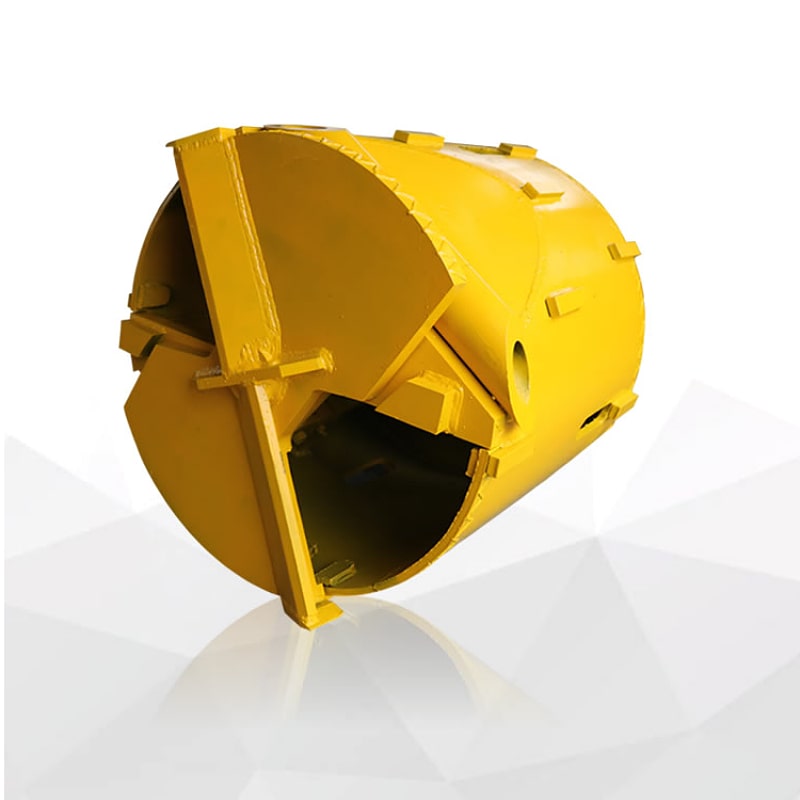

CLEANING BUCKETS

The cleaning buckets are mainly designed to clean the bottom

of Pile. We construct cleaning Bucket with double opening and

single opening. It is mainly used to clean the fine-grained sand, medium coarse soil and clay with hardness of 0 - 12.5 mpa.

BARRELS

CORE BARRELS

Our core Barrel are designed with harden steel and Hard tungsten carbide to Brisement the hard rock formation, which has high strength and durability. It is suitable for drilling in stratification with hardness range of 50-100 mpa.

TECHNICAL SPECIFICATIONS

Shell

Thickness = 30 mm

Height = 1000 mm

Equipment

Betek round shank chisel 0 = 30/38

mm

Kelly box

CROSS CUTTER

The Cross Cutter are heavy-duty tool to archive the greater productivity in the hard rock condition at the range of more than 100 mpa (>100 mpa)

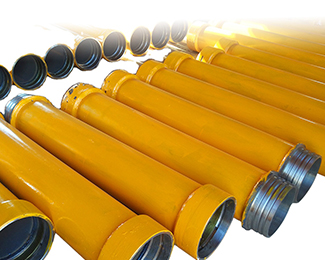

TREMIE PIPES

Basically, Tremie Pipes are used to pour the concrete in to the drilled pile. Our tremie pipes are made of good quality drawn steel pipe in order to guarantee high resistance elements, pipe section can be connected by two kind of joints, one is Threaded and another one is Wire Cable Joints.

• Threaded types are joint together with male and female joints. We prefer up to 6″ diameter for threaded joints.

• Wire Cable types are joint together with pin and box (or) male and female collar. we prefer up to 6″ to 12″.

Funnel: To pour the concrete to the Tremie Pipe.

Lifting Head: It is help to lift (or) lowering operation.

Tremie Stand: It is mainly used to stock the pipes and to move easily from one site to another site.

Tremie Gate: It is for tightening and remove the tremie.

BENTONITE TANKS & MIXER

Bentonite tanks are normally used in the preparation, curing and purification of bentonite slurry, a special mixture used to stabilize the sides of a borehole during drilling: preventing the soils from caving in.

Polymer, when used in conjunction with bentonite in the drilling fluid, enhances viscosity and gel strength, lowers filtration rate, and increases lubricity.

The bentonite mixing and pumping plant is mainly used for the construction of roads, railways, hydropower, construction, mines and other ground and underground projects. The plant is hydraulic drive with compact structure, convenient operation, and the output can be adjustable.

KELLY TERMINAL JOINTS &

AGITATORS

Kelly Terminal Joints

Interlocking kelly bar terminal Joint for your kelly bar maintenance, Length can be required, Kelly bar terminal with kelly strips and inner kelly strips

Agitators

It's used to homogenize media inside a tank. They work by rotating immersed impellers at a controlled speed, also called revolutions per minute (RPM)

WEAR PARTS

Teeth & Holders Available

- Soil Teeth (T25 & T18)

- Rock Teeth ( 25 mm & 32 mm )

- Bucket Spring

Interlocking/Friction/Combined kelly Bar Parts

- Kelly Adapter

- Kelly Spring

- Water Plate, Vertical Pumps